Make The Most Of Productivity: Source Reliable and Affordable Stacking Conveyors for Sale

Make The Most Of Productivity: Source Reliable and Affordable Stacking Conveyors for Sale

Blog Article

Make Best Use Of Reusing Output With Stacking Conveyors: a Crucial Equipment Option

As the need for reusing remains to grow, discovering reliable remedies to make the most of outcome comes to be increasingly important. One such solution that has actually gotten popularity in the recycling industry is making use of piling conveyors. These functional pieces of tools offer numerous advantages, from boosted efficiency to enhanced safety and security. In this conversation, we will check out the numerous sorts of piling conveyors, their applications in reusing, elements to think about when selecting the best conveyor, and beneficial pointers for optimizing recycling output. So, if you're wanting to boost your reusing operations and attain higher degrees of performance, this is a topic you will not intend to miss out on.

Advantages of Stacking Conveyors

Stacking conveyors offer numerous benefits in the recycling sector, improving performance and efficiency while reducing hand-operated labor and lowering functional expenses. One of the key benefits of stacking conveyors is their capacity to pile materials in an organized and space-saving manner.

Piling conveyors also contribute to increased productivity in reusing operations. By effectively piling materials, these conveyors allow quicker and much more streamlined processes, reducing the moment required for arranging and storage space. This, subsequently, permits for a greater throughput of products, leading to raised total performance.

Additionally, using stacking conveyors can considerably decrease functional costs. With automated piling systems, the need for additional workforce is lessened, causing minimized labor costs. Furthermore, by optimizing room use, these conveyors allow reusing facilities to optimize their output without the requirement for costly developments or additional storage space facilities.

Kinds of Stacking Conveyors

When discovering the benefits of stacking conveyors in the reusing market is understanding the different types of piling conveyors readily available,One important element to take into consideration. These conveyors are necessary in making best use of recycling outcome by successfully relocating and piling products.

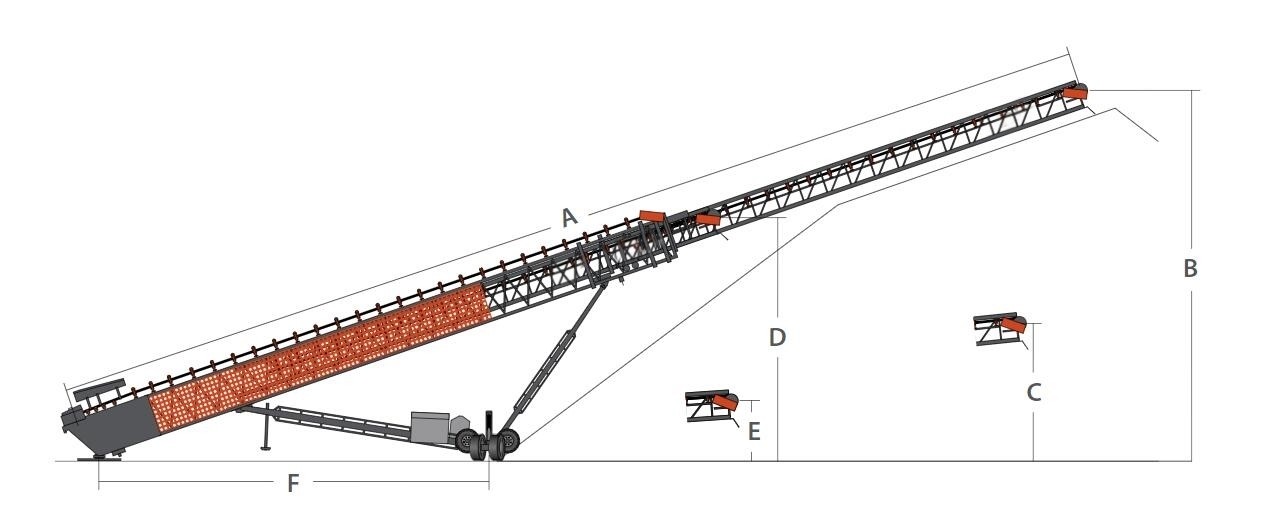

The initial kind of piling conveyor is the radial piling conveyor. This conveyor has a pivot point that allows it to develop a circular accumulation. It can turn as much as 360 degrees, making it possible for products to be uniformly distributed around the stockpile. Radial piling conveyors are generally made use of in applications where adaptability and ability to move are vital.

The second kind is the fixed stacking conveyor. As the name suggests, this conveyor is fixed and does not have the capability to rotate. It is generally used in circumstances where products need to be stacked in a straight line, such as in a sorting or handling center.

A third sort of stacking conveyor is the telescopic piling conveyor. This conveyor has the capacity to prolong and retract, permitting it to reach greater ranges. It is frequently used in applications where materials require to be stacked at various elevations or where area is restricted.

Applications of Piling Conveyors in Recycling

Stacking conveyors play a crucial function in the reusing industry, helping with reliable product activity and piling to make best use of reusing outcome. These functional machines are commonly utilized in different applications within the recycling procedure.

One of the main applications of piling conveyors in recycling is in the sorting and separation phase. Stacking conveyors can be used to transport various kinds of materials, such as paper, glass, steel, and plastic, to designated sorting locations.

Another crucial application of stacking conveyors remains in the storage and stockpiling of recyclable products. They require to be stacked in an organized way for additional processing or transportation when materials have actually been arranged. Piling conveyors enable the creation of small and cool stockpiles, enhancing storage room and promoting easy access for subsequent phases of the reusing process.

Moreover, piling conveyors are typically utilized in the loading and dumping of recyclable materials. They allow the smooth transfer of products in between different stages of the reusing procedure, such as from trucks to arranging lines or from arranging lines to my response storage areas. This effective product movement decreases downtime and boosts total efficiency.

Variables to Think About When Selecting a Piling Conveyor

When selecting a piling conveyor for your recycling operation, it is vital to consider numerous elements to make certain ideal performance and performance. It is vital to select a piling conveyor that can manage the specific products you are functioning with.

Another crucial element to take into consideration is the speed and capacity of the stacking conveyor. The conveyor ought to have the ability to deal with the needed volume of materials without triggering traffic jams or hold-ups in the reusing process. It is likewise crucial to take into consideration the source of power and energy intake of the conveyor to ensure it lines up with your sustainability goals.

Lastly, take into click to investigate consideration the security functions of the stacking conveyor. Look for functions such as emergency situation stop switches, safety and security guards, and indication to shield workers and stop accidents.

Tips for Making The Most Of Recycling Result With Stacking Conveyors

First and primary, regular upkeep is vital for the smooth procedure of stacking conveyors. This consists of routine inspections of electric motors, rollers, and belts to determine and address any kind of prospective concerns before they create major disturbances - stacking conveyors for sale. In addition, lubrication and cleaning must be performed to stop build-up and make certain optimal efficiency

Proper training and education of drivers is another essential variable in making the most of reusing result. Operators should be skilled in the procedure of piling conveyors and conscious of finest practices for dealing with various kinds of products. Clear communication networks and reliable control in between drivers and arranging workers are additionally vital to make certain a smooth circulation of recyclables.

One more tip for optimizing reusing outcome is to enhance the design and arrangement of piling conveyors. This entails considering factors such as the size and weight of products, the quantity of incoming recyclables, and the offered area. By tactically positioning the conveyors and utilizing additional devices like sorting displays and magnets, centers can enhance the reusing process and rise outcome.

Finally, data surveillance and analysis can provide beneficial insights right into the performance of piling conveyors - stacking conveyors for sale. By tracking metrics such as upkeep, throughput, and downtime prices, facilities can recognize areas for renovation and carry out targeted options to enhance effectiveness and productivity

Verdict

Finally, piling conveyors are important tools for making best use of recycling result. They provide countless benefits, such as boosted efficiency and decreased labor expenses. Various sorts of stacking conveyors cater to various recycling applications, supplying convenience and versatility. When picking a stacking conveyor, variables such as toughness, dimension, and capacity must be taken into consideration. By applying piling conveyors and complying with appropriate suggestions, recycling centers can significantly increase their output and add to an advice extra lasting future.

In this conversation, we will discover the various kinds of stacking conveyors, their applications in recycling, variables to think about when picking the best conveyor, and beneficial tips for enhancing reusing result. One of the primary advantages of stacking conveyors is their capability to pile products in an organized and space-saving way.The initial kind of piling conveyor is the radial stacking conveyor.A third type of stacking conveyor is the telescopic stacking conveyor.In final thought, piling conveyors are essential devices for maximizing recycling output.

Report this page